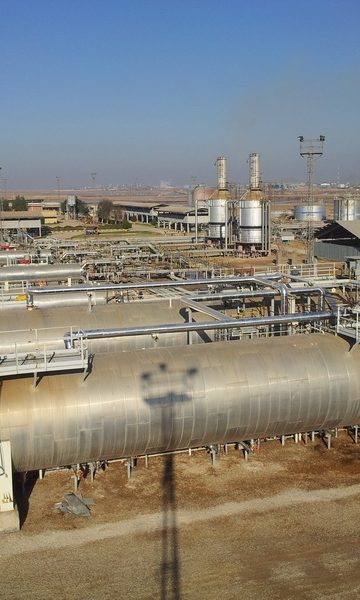

The Indirect Fired Preheaters and Plate Heat Exchangers Project was held in Khuzestan Province by Hirbodan Company in 2007, recommended by National Iranian South Oil Fields Company (NISOC) in the form of EP contract.

Project Scope

- 5 Plate Heat Exchangers, each with 4100 kw duty for “Ahvaz-Asmari 1, 2, 3 & 4 Desalting plants” with Chemical Injection Package (CIP).

- 5 Indirect Fired Preheaters, each with 11.5 MMBtu/h duty and 55,000 b/d design capacity for “Bangestan 1, 2, 3 Desalting plants”.

- 2 Indirect Fired Preheaters and Plate Heat Exchangers, each with 11 MMBtu/h duty and 30,250 b/d design capacity for “Bibi Hakimeh Desalting plant”.

- 2 Indirect Fired Preheaters and Plate Heat Exchangers, each with 15 MMBtu/h duty and 55,000 b/d design capacity for “Pazanan 1 & 2 Desalting plants”.

- 6 Indirect Fired Preheaters and Plate Heat Exchangers, each with 15 MMBtu/h duty and 55,000 b/d design capacity for “Marun-Asmari 1~6 Desalting plants”.

- 1 Indirect Fired Preheater and Plate Heat Exchanger, each with 15 MMBtu/h duty and 55,000 b/d design capacity for “Rag Sefid 2 Desalting plant”.

Project Nature

Hirbodan as the EP contractor was nominated for detail Engineering and Procurement of Plate Heat Exchangers (PHEs) in some Desalting plants near Ahvaz to increase desalting capacity of the plants.

Project Sections

In this project, inlet crude oil to plant is warmed up 20°C in “Plate Heat Exchangers (PHEs)” which work as economizers. The hot side of plate heat exchangers is hot product (desalted) crude oil.

Warmed-up crude oil is then directed to preheating furnaces and increases plant capacity.

Also, preheating furnace in operation units of Bibi Hakimeh & Bangestan 1, 2 & 3 oil fields fell in Hirbodan scope of task in this project as.

The crude oil properties for the Ahvaz & Bangestan locations indicate this fact that the oil has got a relatively high viscosity and lower API gravity. Since, the heat transfer coefficient in Bangestan is higher than that of Bibi Hakimeh 1, there is a demand of large coil to be installed in Bangestan.

With water content, in all cases, specified as 10% of inlet oil, a further design margin of 20% is considered. The fire box ratings and fire-tubes have capacity of 120% firing duty and heat absorption capacities.

Each heater functions and supplies as a single piece of equipment, and is hence suitable to be mounted to the foundation.

The heaters are equipped with fire tube stack, platforms and ladders, burners, fuel gas manifold with hand cocks, control valves indicators, flame arrestor box, expansion tank, instrument and control system, coils pilots, control panel, safety and shut down devices as well as all other necessary provisions for efficient, flexible and safe operation.

Fuel gas line is connected to main gas header with hot tap and equipped with a strainer & regulator to decrease pressure to 100 psig.